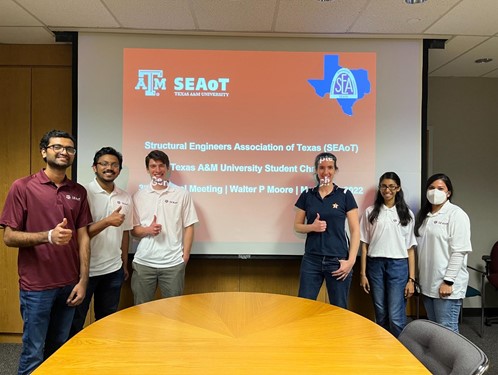

March, 10th 2022 | Walter P Moore | SEAoT TAMU 3rd General Meeting

For the third meeting of the Spring Semester, we had the privilege of hosting Erin Kueht P.E., LEED AP BD+C from Walter P Moore (WPM). First of all, Erin introduced herself briefly and his role at WPM as Project Manager in structure design group. Erin discussed the San Jacinto Community College Ball-Anderson Classroom Buiding, one of the Houston Gulf Coast Region’s first mass timber building and largest mass timber classroom building on a college campus in the U.S.

First of all she listed various wood building systems and different panel options available for slab such as nail laminated, dowel laminated, cross laminated and concrete timber composite panel. The selection of panel depends on aesthetic requirement, availability and strength. The most challenging part of project was fire analysis of building as per IBC code and design for wind load due to its location near to sea shore. Also, the new building was supposed to be erected after the demolition of existing building. So, WPM come with idea of utilizing existing building foundation for new building. After that, she mentioned main structural system used in building – glulam column & beam, steel framing. Wood connection, lateral system for high wind – CLR shear wall and exposed bracing were discussed by her. Then she moved on to construction challenges involved in wood construction such as acoustic and noise study, co-ordination with site team to bore hole for services, erection of crane etc. There are some advantages of using wood deck such as we can use the deck right after erecting. Lastly, she discussed the life cycle cost assessment of building and various parameters need to be consider. Also, the caparison of embodied carbon and structural weight with similar size of steel building were done. Then we had a very informative Q&A session as the last part of the meeting.

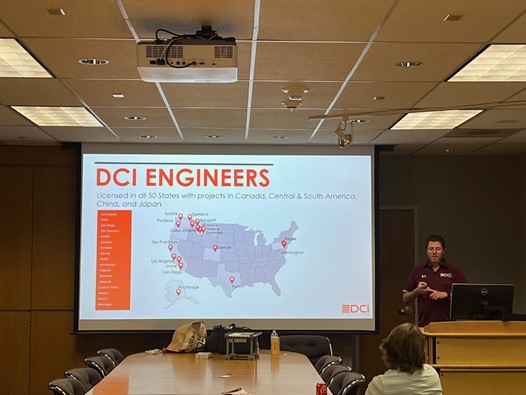

March, 24th 2022 | DCI Engineers | SEAoT TAMU 4th General Meeting

For third meeting we hosted Mike Wilson, P.E. from DCI Engineers. First of all Mike introduced himself and DCI Engineer. Mike gave presentation on how the emerging trend of utilizing prefabricated modular construction can be beneficial to the environment and neighborhood impact, quality of construction, and how it differs from traditional construction in regards to cost, speed of construction, and quality control. He addressed the different design aspects and constraints of modular construction, including building systems, mechanical and electrical challenges, and overall construction cost. He Started with various pre-fab option available in market for modular construction such as shipping container, diversakore, steel box, sustainable living innovation etc. He gave project example of these various construction practice and showed time laps for Stanley hotel in North Dakota, Hawthorne Marriott dual hotel in California. Then went on highlighting benefits of modular construction over conventional construction. Modular construction results in lesser time, higher quality, and reduce cost of construction. However, to achieve these early time collaboration between designer is needed. He also discussed the different layout configuration for example barbell configuration, saw box configuration. At last, he discussed design details for wood and steel assembly including connection details, foundation details, and MEP requirement. He then showed some of modular construction projects of DCI Engineers with budget and site challenges.