TAMU student section of SEAoT is back to holding bi-weekly meetings which started

Fall semester started with a lot of interactions and energy. SEAoT has more plans to do this semester. We started with our bi-weekly meetings and we will continue with game nights, open house and competition along the way. To make this happen, we have added 4 new officers to our executive boards; Pranav Pradeep (PhD student), Amreen Fatima (PhD student), Jay Parmar (Master student), and Emil Robles (Undergraduate student).

In September, we held two general meetings with L.A.Fuess Partners on Sep. 9th and Apis-Cor on Sep. 23rd. In the first session, we had Marlies in-person and Maxwell virtually from L.A. Fuess. After introduction and some general announcement by SEAoT, Maxwell Milan discussed the L.A. Fuess Partner, Inc. and introduced the offices in Dallas, Austin, and Boston and the main duties of each office. He also graphically showed some of the projects done already and the ongoing ones. He then described the camaraderie among all the employees in L.A. Fuess and fascinating working environment. Then he introduced the challenging design of a pedestrian bridge which was 55-foot-long in rural New Mexico. Marlies de Jong was the engineer working on this project. She explained the challenges of how to reach a compromise between the choice of the appropriate section and the weight of the structure in order to comply with the AISC steel design code. Marlies also discussed the vibration analysis performed on the bridge model to attain modal frequencies which was of help for reassuring the avoidance of the mechanical resonance. At the end, Marlies shared her great experiences about how to become a structural engineer, skills she found important to that end and her experience lately as a structural engineer in L.A. Fuess Partner.

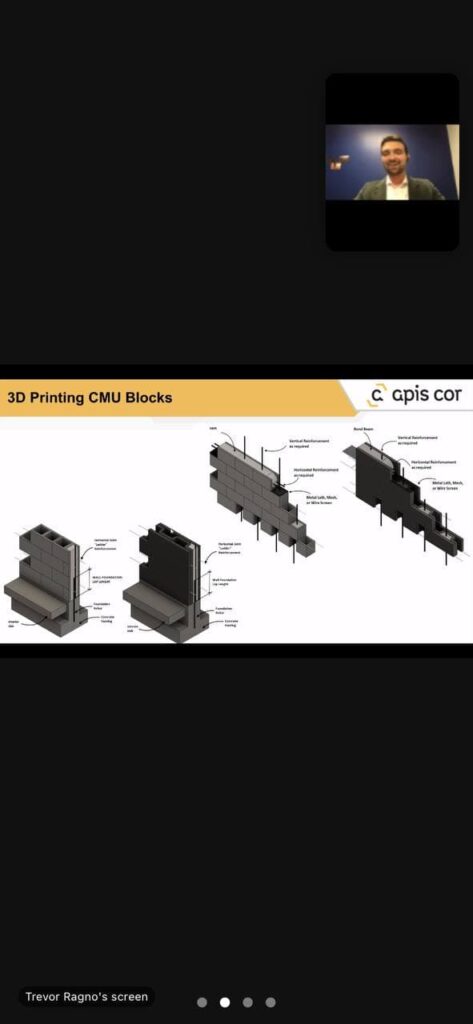

In our second session, we had Apis-Cor virtually from Florida to discuss the largest 3D Printed Concrete project in Dubai. Trevor Ragno discussed challenges in 3D concrete printing construction and its novelty in civil engineering. The importance of concrete material, insulation, connections, climate situation, etc. were described. The infill patterns of the wall and different structural analyses performed on 3D printed concrete models under hazardous loading conditions are discussed. He introduced the Robotic arm 3D printer of Apis-Cor and its ability to construct at different sites. The cost and benefits of this emerging technology was compared to the conventional construction techniques. The active Q&A session was shown how attractive this session was for the attendees.

We had around 30 attendees both in-person and virtually in our first session and around 20 attendees in our second meeting. Some photos of each session are provided here.

Best Regards,

Mohammad Aghajani